|

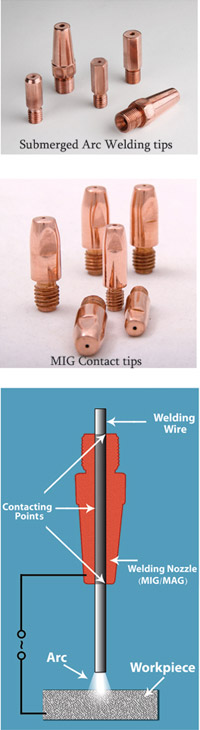

The uniform dispersion of ultra fine AL2O3 particles makes ARTRODE a suitable choice for serving in severe conditions. When high conductivity and wear resistance are required (especially at elevated temperatures) ARTRODE exhibits outstanding performance. For example contact tips in submerged arc welding need to have low electrical resistance, high thermal conductivity, wear resistance and structure stability at high temperatures.

ARTRODE fulfills all of these requirements and can be an excellent substitute for the well established alloys such as Beryllium-Copper or Chromium-Zirconium-Copper.

It shows at least double lifetime as compared to Cu-Cr-Zr and contact tips made from Beryllium-Copper have been successfully replaced by ARTRODE-11 in submerged arc welding of pipes for oil and gas industry resulting in lower cost and longer lifetime.

Other parts made from ARTRODE are MIG welding contact tips. These tips are produced with precise and high finish bore. When welding, the temperature of the tip is raised due to the radiation of the weld pool and the weld current.

ARTRODE's unique resistance to annealing and wear leads to maintaining the original bore dimensions.

Moreover, ARTRODE exhibits a Non-stick behavior to weld spatters which minimizes interruptions associated with metal build up at the tip end.

The overall effect of the above-mentioned facts would be smooth and steady welding which is essential in automatic processes.

A similar application of ARTRODE is the rectangular bar mounted on the top of the control cabin in cable train. These bars must transfer a high current and are exposed to continuous abrasion.

Other applications of ARTRODE are; contact supports, relay blades, lead wire in lamps and high current connectors.

Samples for testing of each case can be provided on customers' requests.