|

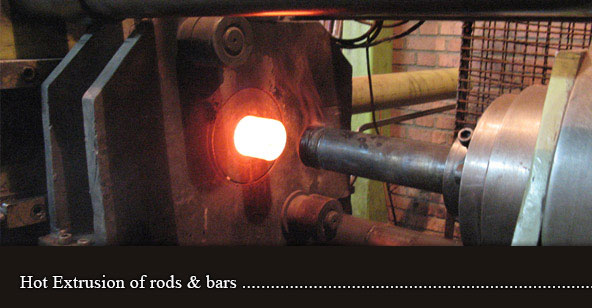

In 1997 an enthusiastic engineer Arash Kamankesh started cold rolling and drawing of copper rods into strips used for conductors and transformers.

At the time persistent demand of automotive industries for spot welding electrode caps made from Cu-Cr-Zr urged us to begin studies about the latest technology of electrode materials. The unsurpassed "Dispersion strengthened copper" became our interest and we decided to produce this unique material. From the early stages of this approach it was quite obvious that our major challenge won't be only the material itself, but the machinery and tooling.

It was such a sophisticated task with numerous problems that sometimes we decided to give up the project. But our passion and determination did not let this happen. We worked around the clock, putting a great effort on this. Fortunately our experience and expertise in metallurgy finally led us to find the technical knowhow and make a pilot plant.

All production stages including powder preparation, powder processing, consolidation and even the cold forming of caps were carried out within the company. Soon after that we were recognized as a reliable manufacturer and "ARTRODE" (our trade name for Cu-Al2O3) was introduced to automotive industries. The high performance and cost effective electrodes made from ARTRODE led to quick acceptance of our product by the market.

The company's rapid growth encouraged us to establish "Artash Composite co.". We are determined to expand the plant and enter the global market.