|

(Alumina Dispersion Strengthened Copper)

This material consists of pure copper containing ultrafine particles of aluminum oxide (10 nm ave size) which are uniformly dispersed in copper matrix. Aluminum oxide is produced by a process during which oxygen reacts with aluminum in copper lattice in the solid state. AL2O3 is very hard and thermally stable. It has no solubility in copper and no AL2O3 growth or diffusion occurs at elevated temperatures. These particles strengthen the copper while minimally reduce its electrical and thermal conductivity.

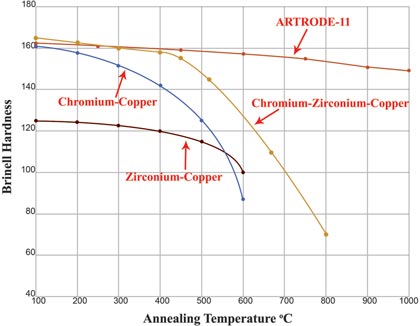

Thus high hardness and tensile strength are inherent properties of ARTRODE and unlike any other copper alloy; it exhibits unique hardness retention after being exposed to elevated temperatures.

This property is caused by the pinning of dislocations by AL2O3 particles and retarding of recrystallization, as a consequence significant softening does not occur due to annealing of ARTRODE even at temperatures close to the melting point of copper.

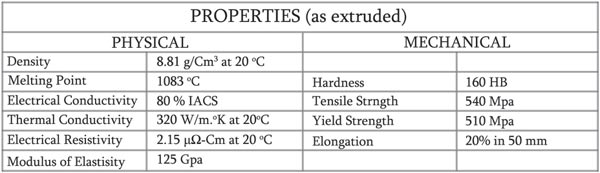

The salient properties of ARTRODE are created by sacrificing little of its electrical conductivity (maintains 78-85% IACS), still its conductivity is comparable to copper and tensile strength to steel.

Artash Composite Co. has developed the production technology of this material all by its own research and development and independent of any other sources.

All production phases, from melting to atomizing of molten metal to metal powder to consolidated bar and even the cold forming of caps used in resistance spot welding are carried out within the company. Contact tips used in submerged arc welding and contact bars in cable train are other products presently made from ARTRODE .

Currently, one grade of this material (ARTRODE-11) is produced. Other grades may be supplied on request.

Properties of ARTRODE-11 are as follows:

ARTRODE-11

- Material Number: UNS C15760

- Classification: R.W.M.A Class-20

- Chemical Composition: Al2O3 (1.1%) by wt. , Copper (balance)

APPLICATIONS:

- Spot Welding Electrodes and Wheels

- Contact tips in MIG and Submerged Arc Welding

- Solder Gun Tips

- Electrical Contacts

AVAILABLE FORMS:

- Round bar 10-20 mm in diameter

- Rectangular bar max cross-sectional

area 320 mm²

MACHINING:

Use carbide tools with chip breaker

Vc: 70-90 m/min

Feeding rate: 0.07-0.15 mm/rev